Sept Issue No. 2 – Maximize Your Incident Reporting and Investigation Results

Most companies wait until after a serious incident occurs to pay attention to their Incident-Investigation reporting system. They use the system to record the incident and document facts, but neglect to use the report that results as a tool to improve workplace safety – skipping the investigation step completely. Here are thethree most important tips for making your incident-investigation reporting procedure as efficient and useful as possible:

- Follow up on your reporting. Record the corrective actions taken to address the hazard at hand and make sure to check in to see if this specific type of injury happens again. You may be putting employees at immediate risk by failing to identify the root causes of an incident or related hazards. A proper framework for observing the repercussions of an incident and how the actions following it affect the short-term outcome is a necessity.

- Look for trends. This is similar to the previous suggestion, but it goes beyond just recording what you do after an incident. Trends only become apparent over long periods of time, so you’ll need to pay attention to this incident and its repercussions for a while in order to ensure safety on your grounds.

- Get your employees involved. Because they are the ones at risk for injuries on the job, it’s important to make sure that all your workers know about hazards and past incidents so that they can take part in their own environmental safety. Since they likely work more closely with hazardous materials and equipment than your management team does, workers will have valuable information to add on what can be done in the future to reduce injuries.

According to Dr. David Michaels, Assistant Secretary of Labor for Occupational Safety and Health, “Accurate records are not simply paperwork, but have an important, in fact, life-saving purpose. They will enable employers, employees, researchers and the government to identify and eliminate the most serious workplace hazards – ones that have already caused injuries and illnesses to occur.”

When a workplace incident occurs, documenting as much detail as possible, such as who, what, where, and when an incident occurred, allows for preventative steps to be implemented. Employers are required to keep accurate records of workplace illness and injuries for up to five years from when the incident occurred.

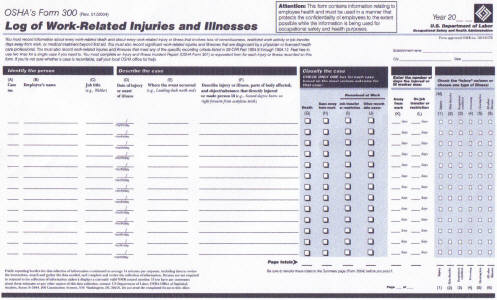

OSHA 300 forms are the reporting forms employers must submit to OSHA when an illness and/or injury occurs from a workplace incident. It’s important to note that employers with fewer than ten full time employees are exempt from OSHA 300 form reporting.

The three different OSHA 300 forms are listed below with descriptions.

OSHA 300 – Comprehensive log of work related injuries and illnesses. The form identifies the person, describes the case, classifies the case, accounts the number of days the worker was away from work, and details the type of injury. Employers must keep the log updated with all workplace illness and injuries.

OSHA 300A – Summary of the OSHA 300 form must be posted for employees by February 1 of the year following the year covered by the form, and employers must keep it posted until April 30 of that year.

OSHA 301 – Detailed injury and illness injury report. Sensitive information is recorded on the OSHA 301 form and all sensitive information must be kept confidential. This form must be completed if any of the following result from a workplace incident: death, loss of consciousness, professional medical treatment beyond first aid, or one or more days of lost work beyond the incident date.

Quantum’s Incident Reporting/Investigation/Corrective Action Module The completed forms can even be uploaded into the system so companies can reprint the forms to show compliance when asked to do so. For more information on how a good incident reporting system can improve safety culture within an organization, click here to read an article written by my colleague, Cassandra Seltzer.

Pedestrians already know that they need to be aware of their surroundings – any kind of car can lose control. But truck accidents are the most dangerous kinds of impact. In the workplace, common-sense rules of the road should be applied when around lift trucks. Thousands of lift truck accidents occur every year, some even resulting in deaths. Lift truck accidents are especially dangerous because the pedestrian is struck not only by the truck itself but also by whatever it is lifting.

Reports on lift truck accidents tend to be hazy on the exact details of the incident. This may be due to unstandardized reporting rules or to intentional withholding on the company’s part because of their own standards or reporting choices. What we do know is that accidents occur roughly as often with reversing trucks as with those moving forward, and many of the accidents happen to people working closely with the lift operator at the time of collision.

Even though specific instructions will not apply to all cases of lift truck accidents, there are still a few key points that should be addressed to improve overall workplace safety and reduce the likelihood of lift truck accidents.

- Workers using the lift trucks and those working around them should all be trained properly on lift truck safety and what to do in case of emergency.

- It is also helpful to establish separate areas in which lift trucks and pedestrians can travel in order to physically remove ground workers from the area surrounding the trucks.

- Limiting lift truck speeds will further help save workers’ lives, since they will have more time to move out of the way and lift truck operators will have better control of their vehicles.

Overall, lift truck safety should be a much more heavily investigated category of incident than it is currently. Without proper data, OSHA cannot create specific standards for companies to enforce. Incident reporting is therefore key to preventing as many lift truck accidents as possible, saving your company time, and saving employees from serious harm.

CONTACT US

"*" indicates required fields