In the realm of workplace safety and regulatory compliance, the importance of accurate and effective hazard communication cannot be overstated. One of the key components of this communication is GHS Label Printing. As technology advances, innovations in GHS Label Printing are transforming the way organizations manage chemical safety information. This article explores the latest developments in GHS Label Printing and how they contribute to ensuring safety and compliance.

The Role of GHS Label Printing in Safety and Compliance

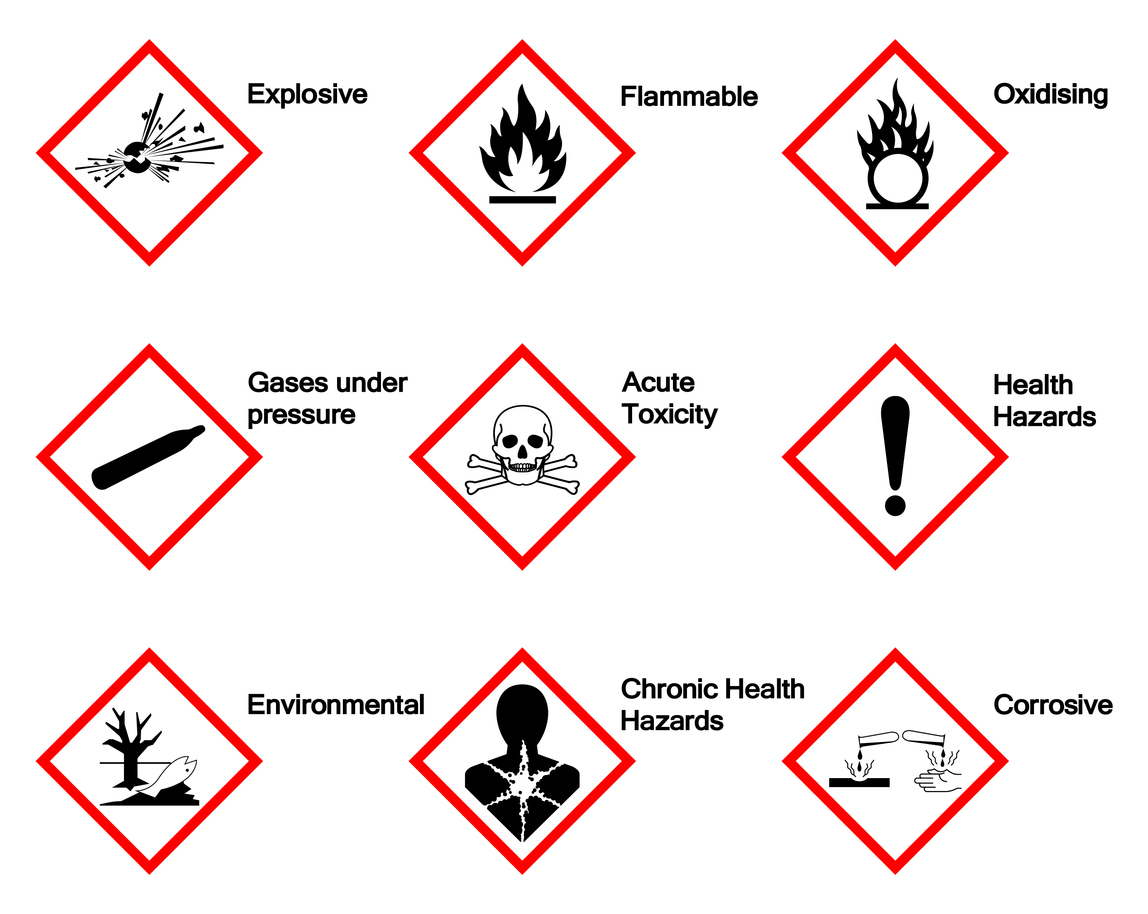

GHS Label Printing is essential for creating labels that convey critical information about hazardous chemicals. These labels include details such as chemical identity, hazard pictograms, signal words, hazard statements, precautionary statements, and supplier information. Accurate and durable GHS Label Printing ensures that this information remains legible and accessible, which is crucial for maintaining workplace safety and meeting regulatory requirements.

Innovations in GHS Label Printing

- Advanced Printing Technologies:

Recent advancements in printing technologies have significantly improved GHS Label Printing. High-resolution printers now produce labels with sharper text and clearer images, enhancing readability. These advancements ensure that hazard information is easily understood by all employees, reducing the risk of accidents.

- Durable Materials:

One of the major innovations in GHS Label Printing is the development of more durable materials. Labels printed on these materials can withstand harsh environmental conditions, such as exposure to chemicals, water, and extreme temperatures. This durability ensures that GHS labels remain intact and legible over time, maintaining compliance and safety standards.

- On-Demand Printing:

On-demand GHS Label Printing allows organizations to print labels as needed, reducing waste and ensuring that the most current information is always used. This flexibility is particularly beneficial for companies that frequently update their chemical inventories or change suppliers.

- Integrated Software Solutions:

Modern GHS Label Printing systems often include integrated software solutions that streamline the label creation process. These software tools can automatically populate labels with the correct information from a database, ensuring accuracy and compliance. Additionally, they can generate labels in multiple languages, catering to diverse workforces.

- Customization Options:

Innovations in GHS Label Printing now offer greater customization options, allowing companies to tailor labels to their specific needs. Customization can include adding company logos, specific hazard statements, or additional safety instructions, enhancing the effectiveness of hazard communication.

- Eco-Friendly Printing:

Sustainable practices are becoming increasingly important in all industries. Innovations in GHS Label Printing now include eco-friendly options, such as using recyclable materials and inks with lower environmental impact. These practices help companies reduce their carbon footprint while maintaining compliance.

Benefits of Modern GHS Label Printing Innovations

- Enhanced Safety:

Improved readability and durability of GHS labels directly contribute to enhanced workplace safety. Employees can quickly and easily identify hazards and follow appropriate safety measures, reducing the risk of accidents and injuries.

- Increased Compliance:

Accurate and up-to-date GHS Label Printing ensures that companies remain compliant with international safety regulations, such as OSHA’s Hazard Communication Standard (HCS) and the Globally Harmonized System (GHS). Compliance helps avoid fines and legal issues while promoting a culture of safety.

- Cost Efficiency:

On-demand GHS Label Printing and durable materials reduce the need for frequent replacements, lowering overall costs. Additionally, integrated software solutions minimize errors and streamline the label creation process, saving time and resources.

- Improved Flexibility:

The ability to customize labels and print them on demand provides organizations with the flexibility to adapt to changing needs. This adaptability is crucial for companies that handle a wide variety of chemicals or operate in dynamic environments.

- Environmental Responsibility:

Eco-friendly GHS Label Printing options allow companies to meet their sustainability goals without compromising on safety or compliance. Using recyclable materials and environmentally friendly inks demonstrates a commitment to responsible practices.

Case Study: Successful Implementation of Innovative GHS Label Printing

A chemical manufacturing company recently adopted an advanced GHS Label Printing system to address challenges related to label durability and compliance. By implementing on-demand printing and using durable materials, the company achieved the following results:

- Reduced Costs: On-demand printing reduced waste and minimized the need for frequent label replacements.

- Enhanced Safety: Durable labels with clear hazard information improved overall workplace safety.

- Increased Compliance: The integrated software ensured that all labels met regulatory requirements, reducing the risk of non-compliance.

Conclusion

Innovations in GHS Label Printing are revolutionizing the way organizations manage chemical safety information. Advanced printing technologies, durable materials, on-demand printing, integrated software solutions, customization options, and eco-friendly practices all contribute to more effective hazard communication. By embracing these innovations, companies can enhance safety, ensure compliance, and achieve greater cost efficiency. Investing in modern GHS Label Printing solutions is a strategic move that underscores a commitment to workplace safety and regulatory adherence.